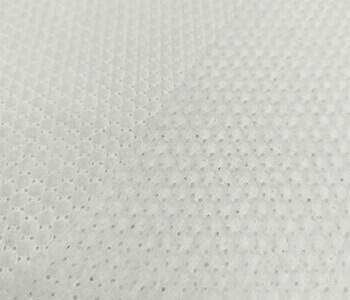

Six-Hole Pearl Perforated Hot Air Nonwoven Fabric

Here’s how Six-Hole Pearl Perforated Hot Air Nonwoven Fabric is typically produced:

Raw Materials

- High-quality polymers like polypropylene (PP).

- Additives for enhanced properties.

Fiber Formation

- Meltblowing/Spunbonding: Polymer melted and extruded into filaments.

- Web Formation: Filaments laid on a moving belt to form a uniform web.

Thermal Bonding

- Hot Air Process: Hot air blown through the web to bond fibers.

- Calendering (Optional): Heated rollers for additional bonding.

Perforation

- Six-Hole Perforation: Mechanical or laser perforation to create the six-hole pattern.

- Pearl Texture: Embossing for a soft, exfoliating surface.

Finishing Treatments

- Hydrophobic Treatment: To repel liquids.

- Softening: Agents added for improved feel.

Cutting and Packaging

- Cutting: Fabric cut into desired shapes and sizes.

- Packaging: Packaged for hygiene and ease of use.

key Characteristics

- Enhanced Absorbency: The six-hole perforations increase the fabric’s surface area, enhancing its ability to absorb liquids.

- Gentle Exfoliation: The pearl texture provides a mild exfoliating effect, beneficial for personal care products.

- Softness: Ensures comfort, making it suitable for direct skin contact applications.

- Breathability: The hot air nonwoven manufacturing process ensures breathability, maintaining comfort and preventing moisture build-up.

- Durability: Resistant to wear and tear, ensuring long-lasting use in various applications.

- Eco-Friendly Options: Can be designed to be biodegradable, offering environmentally friendly choices for consumers.

Application

MEDICAL

Disposable KN95/N95 Mask

HYGIENE

Baby diapers, adult diapers, pads, adsorbentscleaning wipes