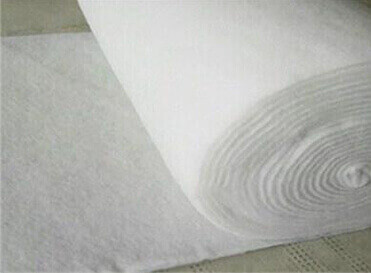

100% Cotton Spunlace Nonwoven Fabric for Cotton Soft Wipes

Here’s how 100% Cotton Spunlace Nonwoven Fabric for Cotton Soft Wipes is typically produced:

Fiber Preparation:

- Cotton Fiber Selection: High-quality cotton fibers are selected.

- Opening and Cleaning: The cotton fibers are opened and cleaned to remove impurities.

Web Formation:

- Carding: The cleaned cotton fibers are carded to create a uniform web.

Hydroentanglement:

- Water Jet Entanglement: The cotton web is passed through high-pressure water jets, entangling the fibers to form a cohesive fabric.

Dewatering and Drying:

- Dewatering: Excess water is removed from the fabric.

- Drying: The fabric is dried to achieve the desired moisture level.

Finishing:

- Calendaring: The fabric may be passed through heated rollers to smooth the surface (optional).

- Chemical Treatments: Optional treatments can enhance properties like softness or antimicrobial features.

key Characteristics

Softness: The fabric is exceptionally soft, making it ideal for products that come into contact with the skin, especially sensitive areas like the face and baby skin.

Absorbency: Cotton fibers have high absorbency, which ensures effective cleaning and liquid absorption, suitable for personal hygiene and cleaning tasks.

Biodegradability: Made from 100% cotton, the fabric is fully biodegradable, providing an environmentally friendly alternative.

Hypoallergenic: Naturally hypoallergenic and free from synthetic chemicals, making it safe for sensitive skin and reducing the risk of allergic reactions.

Strength: Despite its softness, the spunlace process gives the fabric sufficient strength and durability to withstand use without tearing.

Lint-free: The fabric produces minimal lint, ensuring that it leaves no residue on the skin or surfaces being cleaned.

Application

MEDICAL

Disposable KN95/N95 mask

CLOTHING

Clothing interlining fabric, artificial leather base fabric/shoe lining

HOUSEHOLD

Nonwoven curtains, carpets

AUTOMOTIVE

Car interior lining

CONSTRUCTION

Asphalt felt base fabric

GEOTEXTILE

Geotextile

INDUSTRY

PET skeleton fabric