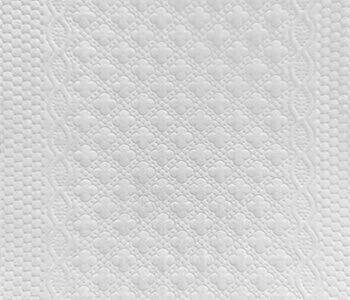

Velvet Clover Hot Air Nonwoven Fabric

Here’s how Velvet Clover Hot Air Nonwoven Fabric is typically produced:

- Raw Material Preparation: Selection and opening of high-quality fibers (e.g., polyester, polypropylene).

- Web Formation: Carding to align fibers into a loose web, then laying the web on a moving belt to form a continuous sheet.

- Bonding: Passing the web through a hot air oven to bond fibers using hot air through bonding, with precise temperature control to ensure consistent bonding without damaging fibers.

- Finishing: Calendering to smooth the fabric with heated rollers, followed by cutting and slitting to size the fabric.

key Characteristics

- Softness: The fabric is exceptionally soft to the touch, making it ideal for products that come into direct contact with the skin.

- Breathability: The hot air through bonding process allows for good air permeability, enhancing comfort.

- Absorbency: It has excellent liquid absorption properties, which is beneficial for hygiene products.

- Lightweight: The fabric is lightweight yet durable, providing strength without added bulk.

- Non-irritating: It is designed to be gentle on the skin, minimizing the risk of irritation.

- Eco-friendly: Often, these fabrics are made from biodegradable materials, contributing to environmental sustainability.

Application

MEDICAL

Disposable KN95/N95 Mask

HYGIENE

Baby diapers, adult diapers, pads, adsorbentscleaning wipes