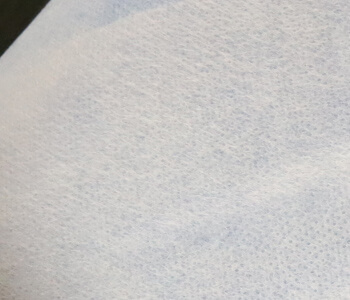

S Spunbond Nonwoven Fabric

Here’s how S spunbond nonwoven fabric is typically produced:

Extrusion: The process begins with the extrusion of polymer pellets, usually polypropylene (PP) or polyester (PET), into continuous filaments.

Spinning: The extruded filaments are then spun onto a conveyor belt or drum in a random or directional orientation, forming a web of fibers.

Bonding: The web of fibers is then bonded together using heat, pressure, or chemicals. Heat and pressure are the most common bonding methods in spunbond technology. The bonding process creates a cohesive fabric structure.

key Characteristics

Uniformity: Single spunbond nonwoven fabric is known for its uniformity in terms of thickness, density, and structure. This uniformity ensures consistent performance and reliability in various applications.

Strength and Durability: Despite its lightweight nature, single spunbond fabric offers excellent strength and durability. It can withstand mechanical stresses and is resistant to tearing and puncturing, making it suitable for applications requiring robust materials.

Breathability: Single spunbond nonwoven fabric typically provides good breathability, allowing air to pass through easily. This property makes it comfortable to wear and suitable for applications where airflow is essential, such as hygiene products and protective apparel.

Water Resistance: Depending on specific manufacturing processes and treatments, single spunbond fabric can be engineered to be water-resistant or even waterproof. This makes it suitable for applications requiring moisture protection, such as medical drapes and packaging materials.

Chemical Resistance: Single spunbond nonwoven fabric can exhibit resistance to various chemicals, oils, and solvents, depending on the type of polymer used in its production. This property enhances its suitability for industrial applications where exposure to chemicals is common.

Application

MEDICAL

Gowns, cowlings, shoecovers, face masks, hospital bed linens, single use garments

PACKAGING

Transportation (sickbags, envelopes, bags, promotional materials), Protection (sterilization, wrapping, electronic products, leather goods,cosmetics, bulk products), Others

PROTECTIVE CLOTHING

Chemical handling, decontamination of contaminated land, decommissioning of production plants, oil handling, oil tanker cleaning hazardous waste clean-up

ROOFING AND BUILDING

Thermal and acoustic insulation, walls covering waterproofing membranes, vapour barriers, flooring substrates, foundations and soil stabilization, pipewrap

AGRICULTURE AND HORTICOLTURE

Crop cover, frost protection, green house shading, mulching, hobby gardening, insect protection, root bag, weed control, seed blanket, capillary matting

AUTOMOTIVE

Interiors (headliner, face fabric, dashboard insulation, carpets and flooring, seat backing,upholstery, spring covers, interior trim, parcel shelf, separation and wrapping layer for injection moulding components)

ELECTRIC AND ELECTRONICS

Cables wrapping, fuel cell, battery separators insulating tape

FILTRATION

Air (ventilation and air conditioning, vacuum cleaners, cooker hoods, clean rooms), Liquids(food & beverage, water, blood, hydraulic), Automotive (engine air, oil, fuel, cabin air)

HOUSEHOLD

Quilt backing, blankets, pillow cases, curtains.table linen, dust covers, wipes, fabric softener sheets, abrasives, spring wrap, mattress pad components

FOOD AND BEVERAGE

Food packaging, tea and coffee bags, absorbent pads

HYGIENE

Baby diapers, adult diapers, pads, adsorbentscleaning wipes

CLOTHING

Disposable sauna suit, clothes dust cover