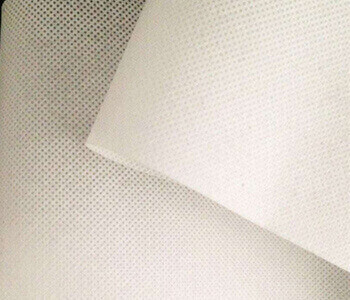

SMMS Composite Nonwoven Fabric

Here’s how SMMS Composite Nonwoven Fabric is typically produced:

First Spunbond Layer: Thermoplastic polymer (usually polypropylene) is melted and extruded through spinnerets to form continuous filaments, which are laid down to form a nonwoven web.

First Meltblown Layer: Another layer of thermoplastic polymer is melted and extruded through fine nozzles with high-velocity air to create fine fibers, forming a dense, porous web.

Second Meltblown Layer: A second meltblown layer is added on top of the first, further enhancing the barrier and filtration properties.

Second Spunbond Layer: A final layer of spunbond material is added on top, creating the four-layer structure.

Bonding: The layers are bonded together using heat, pressure, or adhesives to form the final SMMS fabric.

key Characteristics

Enhanced Strength: The spunbond layers provide excellent tensile strength and durability, making the fabric resistant to tearing and stretching.

Superior Barrier Protection: The double meltblown layers offer high filtration efficiency, acting as a strong barrier against fluids, particulates, and microbes.

Breathability: Despite its robust barrier properties, SMMS fabric remains breathable, allowing air and moisture vapor to pass through, which enhances comfort in various applications.

Softness: SMMS fabric can be engineered to be soft to the touch, making it comfortable for applications involving direct contact with the skin.

Chemical Resistance: Depending on the type of polymer used, SMMS fabric can exhibit resistance to various chemicals, making it suitable for industrial and medical uses.

Versatility: The combination of two spunbond layers and two meltblown layers allows for a versatile range of properties, making SMMS fabric suitable for diverse applications.

Application

MEDICAL

Gowns, cowlings, shoecovers, face masks, hospital bed linens, single use garments

HYGIENE

Baby diapers, adult diapers, pads, adsorbentscleaning wipes

CLOTHING

Disposable sauna suit, clothes dust cover

INDUSTRY

Oil absorbent strips (oil absorbent ropes), paint spraying protective clothing, disposable dustproof clothing

FILTRATION

Air (ventilation and air conditioning, vacuum cleaners, cooker hoods, clean rooms), Liquids(food & beverage, water, blood, hydraulic), Automotive (engine air, oil, fuel, cabin air)

HOUSEHOLD

Quilt backing, blankets, pillow cases, curtains.table linen, dust covers, wipes, fabric softener sheets, abrasives, spring wrap, mattress pad components

AUTOMOTIVE

Interiors (headliner, face fabric, dashboard insulation, carpets and flooring, seat backing,upholstery, spring covers, interior trim, parcel shelf, separation and wrapping layer for injection moulding components)