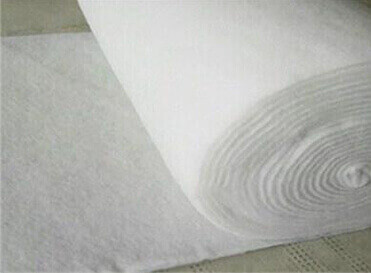

100% Cotton Spunlace Nonwoven Fabric

Here’s how 100% Cotton Spunlace Nonwoven Fabric is typically produced:

Fiber Preparation:

- Cotton Fiber Selection: Choose high-quality cotton fibers.

- Opening and Cleaning: Open and clean the fibers to remove impurities.

Web Formation:

- Carding: Comb the cotton fibers to create a thin, loose web.

Hydroentanglement:

- Water Jet Entanglement: Pass the cotton web through high-pressure water jets to entangle the fibers and form a cohesive fabric.

Dewatering and Drying:

- Dewatering: Remove excess water from the fabric.

- Drying: Dry the fabric to achieve the desired moisture level.

Finishing:

- Calendaring: Smooth the fabric surface by passing it through heated rollers (optional).

- Chemical Treatments: Apply treatments to improve properties like softness or absorbency (optional).

Winding and Slitting:

- Wind the finished fabric onto rolls and slit to desired widths.

Quality Control:

- Perform quality checks to ensure the fabric meets required standards.

key Characteristics

Softness: Extremely soft and gentle, making it ideal for applications involving direct skin contact, such as baby wipes and facial wipes.

Absorbency: High absorbency due to the natural properties of cotton fibers, which makes it effective for cleaning, medical, and hygiene applications.

Biodegradability: Fully biodegradable and environmentally friendly, offering a sustainable alternative to synthetic nonwovens.

Breathability: Good air permeability, enhancing comfort in applications like medical dressings and personal care products.

Strength: Despite its softness, it has good tensile strength and durability, suitable for both disposable and some reusable applications.

Hypoallergenic: Naturally hypoallergenic and free from synthetic chemicals, making it safe for sensitive skin and reducing the risk of allergic reactions.

Lint-free: Typically has low linting properties, which is important in medical and hygiene products to maintain cleanliness.

Chemical-Free: Free from synthetic binders and adhesives, relying solely on mechanical entanglement for fabric formation.

Natural Feel: Provides a natural and comfortable feel, preferred in many personal care and cosmetic applications.

Versatility: Can be manufactured in various weights and thicknesses to suit different needs, from lightweight facial tissues to heavier cleaning wipes.

Application

MEDICAL

Disposable KN95/N95 mask

CLOTHING

Clothing interlining fabric, artificial leather base fabric/shoe lining

HOUSEHOLD

Nonwoven curtains, carpets

AUTOMOTIVE

Car interior lining

CONSTRUCTION

Asphalt felt base fabric

GEOTEXTILE

Geotextile

INDUSTRY

PET skeleton fabric