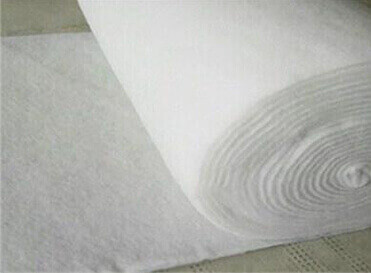

Bamboo Fiber Spunlace Nonwoven Fabric

Here’s how Bamboo Fiber Spunlace Nonwoven Fabric is typically produced:

Bamboo Fiber Preparation: Bamboo is harvested and processed to extract fibers. The fibers are then cleaned and prepared for manufacturing.

Blending and Web Formation: Bamboo fibers are blended and formed into a web using a web forming machine.

Spunlace Process: The web of bamboo fibers is subjected to high-pressure water jets in a spunlace machine, entangling the fibers to form a strong and durable nonwoven fabric.

Finishing: After the spunlace process, the fabric may undergo additional treatments such as drying, heat setting, and optional finishing treatments like antibacterial coatings.

key Characteristics

Natural and Eco-friendly: Made from bamboo fibers, which are renewable and biodegradable, making it environmentally sustainable.

Soft and Comfortable: Bamboo fibers are naturally smooth and soft to the touch, making the fabric gentle on the skin.

High Absorbency: Bamboo fibers have excellent moisture absorption properties, making this fabric ideal for products requiring high absorbency.

Breathability: The structure of bamboo fiber allows for good air permeability, keeping the skin cool and comfortable.

Antibacterial and Antimicrobial: Bamboo fibers possess natural antibacterial properties, reducing the growth of bacteria and odor.

Biodegradable: Bamboo is a naturally biodegradable material, contributing to reduced environmental impact.

Application

MEDICAL

Disposable KN95/N95 mask

CLOTHING

Clothing interlining fabric, artificial leather base fabric/shoe lining

HOUSEHOLD

Nonwoven curtains, carpets

AUTOMOTIVE

Car interior lining

CONSTRUCTION

Asphalt felt base fabric

GEOTEXTILE

Geotextile

INDUSTRY

PET skeleton fabric