Here’s how Bicomponent Spunlace Nonwoven Fabric is typically produced:

Fiber Selection and Mixing: Polyester and polyamide fibers are selected and blended in specific ratios based on the desired performance characteristics.

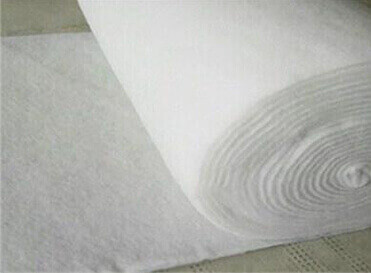

Web Formation: The blended fibers are fed into a web forming machine to create a uniform web structure.

Spunlace Process: The web is passed through a spunlace machine where high-pressure water jets entangle the fibers to form a strong and durable nonwoven fabric.

Finishing: After the spunlace process, the fabric may undergo additional treatments such as heat setting to stabilize its dimensions and enhance its properties.

Bi-component Structure: Composed of two different types of fibers, each contributing unique properties to the fabric.

Strength and Durability: The combination of polyester and polyamide fibers enhances the fabric’s strength and durability.

Absorbency: Can be tailored to achieve different levels of absorbency by adjusting the ratio of polyester to polyamide fibers.

Softness and Comfort: Offers a soft and comfortable texture, suitable for applications requiring direct contact with the skin.

Versatility: Suitable for a wide range of applications due to its customizable properties and performance characteristics.

Filtration Efficiency: Can be used effectively as a filtration material due to its fine fiber structure.

Disposable KN95/N95 mask

Clothing interlining fabric, artificial leather base fabric/shoe lining

Nonwoven curtains, carpets

Car interior lining

Asphalt felt base fabric

Geotextile

PET skeleton fabric