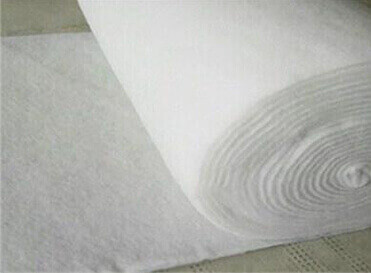

Spunlaced Nonwoven Fabric

Here’s how Spunlaced Nonwoven Fabric is typically produced:

- Fiber Preparation:

- Raw fibers (natural or synthetic) are opened, cleaned, and blended.

- Web Formation:

- The fibers are laid down randomly to form a loose web using carding or airlaying machines.

- Hydroentanglement:

- The web passes through high-pressure water jets, which entangle the fibers together to form a fabric.

- Drying and Finishing:

- Excess water is removed from the fabric, and it is dried using hot air.

- Optional finishing treatments like calendaring (smoothing) or chemical treatments (for softness or other properties) may be applied.

- Winding and Quality Control:

- The finished fabric is wound onto rolls and undergoes quality checks to ensure it meets specifications for strength, thickness, and other properties.

key Characteristics

Softness: Spunlaced fabrics are known for their soft and gentle feel, making them comfortable for use in sensitive applications.

Strength: They exhibit good tensile strength and durability, which is important for withstanding handling and use in various products.

Absorbency: Depending on the type of fibers used (like cotton, viscose, or blends), spunlaced fabrics can be highly absorbent, making them ideal for products like wipes and medical dressings.

Lint-free: Spunlaced fabrics typically have low linting properties, which is advantageous in applications where cleanliness and hygiene are critical.

Breathability: They are breathable fabrics, allowing for good air permeability.

Versatility: Spunlaced nonwoven fabrics can be manufactured in various weights, thicknesses, and fiber compositions to meet specific performance requirements.

Drapeability: They have good drape characteristics, conforming well to shapes and contours.

Smooth Surface: The surface of spunlaced fabrics is generally smooth, making them suitable for applications where a soft touch is desired.

Biodegradability: Depending on the fibers used, spunlaced fabrics can be biodegradable, contributing to sustainability efforts.

Chemical Compatibility: They can be treated or engineered to have specific chemical resistances, enhancing their suitability for different environments and applications.

Application

MEDICAL

Disposable KN95/N95 mask

CLOTHING

Clothing interlining fabric, artificial leather base fabric/shoe lining

HOUSEHOLD

Nonwoven curtains, carpets

AUTOMOTIVE

Car interior lining

CONSTRUCTION

Asphalt felt base fabric

GEOTEXTILE

Geotextile

INDUSTRY

PET skeleton fabric

Spunlaced Nonwoven Fabric

Spunlaced Nonwoven Fabrics spray high-pressure fine water onto one or more layers of fiber webs to entangle the fibers with each other, thereby strengthening the fiber webs.